FEDI®

Fractional Electrodeionization

Produce ultrapure water (up to 18 M Ω.cm) without any hazardous chemicals using Fractional Electrodeionization (FEDI) – an advanced version of Electrodeionization (EDI) technology. It requires significantly less energy and can tolerate higher hardness feeds compared to conventional EDI. FEDI lowers the risk of scaling and improves plant design economics and reliability.

This two-stage patented technology by QUA, solves the limitations of EDI to allow industries produce continuous ultrapure water for various industrial applications. FEDI is engineered for industries requiring the highest purity process water, including semiconductor and solar panel manufacturing, power generation, refining, pharmaceuticals, biomedical and food & beverage.

Ultrapure Water Production

Capable of generating ultrapure water (up to 18 MΩ.cm) with high silica and boron rejection.

Chemical-Free Process

Eliminates the need to store and handle hazardous chemicals for resin regeneration and associated neutralization steps.

High Hardness Tolerance

Reduces the potential for hardness scaling. It helps improve system reliability.

Continuous Operation

Provides a continuous supply of pure water without interruptions for chemical regeneration, unlike traditional ion exchange.

Energy-efficient

Uses higher electrical current only where required for efficiency that saves considerable power.

Hot Water Sanitization

Essential for pharmaceutical, biomedical, and laboratory applications to meet stringent sanitization requirements.

How Does FEDI® Work?

Producing ultrapure water requires removal of both strongly ionized impurities (hardness) and weakly ionized impurities (silica & boron). More weakly ionized impurities require higher voltage and/or current for effective removal. However, single-stage EDI systems struggle to effectively remove boron and silica, as the high current required for effective removal risks causing hardness to precipitate and scale in the system.

FEDI takes a two-stage approach, applying different currents, and in some cases different voltages, to address strongly and weakly ionized impurities in sequence. In the first stage, strongly ionized impurities such as hardness are removed, lowering the scaling potential of the feed. In the second stage, weakly ionized impurities such as silica & boron are removed by applying higher voltage and current.

The two-stage approach of QUA’s FEDI technology ensures that stage 2 will remains in a highly regenerated stage, resulting in superior product water quality. Customizing voltage and current to strongly and weakly ionized impurities reduces operating costs by improving energy efficiency and avoiding scaling.

Applications of FEDI®

High-pressure boiler feedwater in power plants

High-pressure boiler feedwater in power plants

Wafer cleaning and rinsing in semiconductor and electronics manufacturing

Wafer cleaning and rinsing in semiconductor and electronics manufacturing

Purified water for formulation, cleaning, and manufacturing in the pharma industry

Purified water for formulation, cleaning, and manufacturing in the pharma industry

Silicon wafer cleaning in solar industry

Silicon wafer cleaning in solar industry

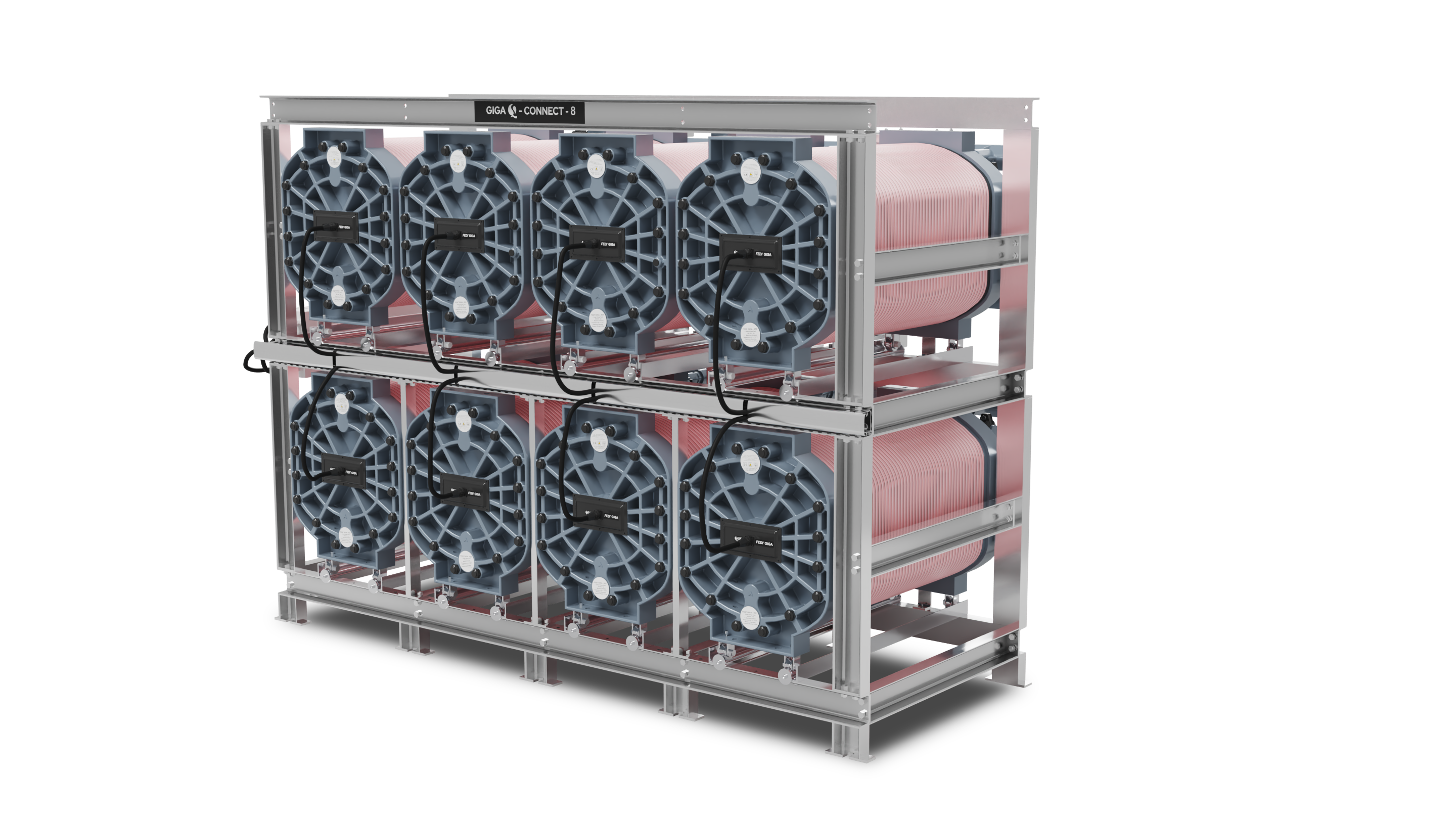

FEDI® GIGA Q-Connect

FEDI® GIGA Q-Connect is a modular configuration comprising of multiple FEDI® GIGA units, designed for very high-flow ultrapure water applications. It is delivered as a pre-engineered assembly to significantly reduce engineering & on-site installation man-hours. The system operates with only three headers—feed, permeate, and reject—minimizing piping, instrumentation, and design complexity.